Over the last thirty years, logistics has undergone a tremendous change: from a purely operational function that reported to sales or manufacturing and focused on ensuring the supply of production lines and the delivery to customers, to an independent SCM function. According to a report by Fortune Business Insights, the Industry 4.0 market is projected to reach USD 337.10 Billion in 2028.

Several technologies have emerged that are altering traditional ways of working. On top of this, mega trends and customer expectations change the game. Besides the need to adapt, supply chains also have the opportunity to reach the next horizon of operational effectiveness, to leverage emerging business models, and to transform the company into a digital supply chain.

Pressure to reduce carbon emissions as well as regulations of traffic for socioeconomic reasons add to the challenges that logistics are facing. However, changing demographics also lead to reduced labor availability as well as increasing ergonomic requirements that arise as the workforce age increases.

Simultaneously, customer expectations are growing and a very definite trend towards further individualization and customization drives the strong growth and constant changes in the SKU portfolio. The online-enabled transparency and easy access to a multitude of options regarding places to shop and buy drives the competition of supply chains.

To build on these trends and cope with the changed requirements, supply chains need to become much faster, more granular, and much more precise.

What is Supply Chain 4.0?

- Supply Chain 4.0 is the re-organization of supply chains – design and planning, production, distribution, consumption, inventory and logistics – using technologies that are known as “Industry 4.0”

- Using advanced robotics, Internet of Things (IoT), advanced big data analytics, AI and Automation, Supply Chain 4.0, integrates sensors everywhere, programs processes, analyzes every result to augment production, improve performance, stir innovation and growth opportunities

- These digital technologies ensure smart supply chain management, transforming it from a linear model to one where information flows from one centralized source to multiple directions

Need for Supply Chain 4.0

Evolving supply chain operations through agile and resilient solutions

- Creating intelligent workflows to strategically improve the overall supply chain process and enhance security

- With the help of advanced analytics, AI and blockchain building a resilient supply chain against disruption and uncertainties

- Implementing business and process improvement solutions

- Monitoring them continuously and process rectifications where necessary creates minimizes the risk of operations

Adequacy of the level of autonomy and intelligence in logistics

- Injecting more efficiency, effectivity, agility to establish smart and connected logistics aligned to meet the needs of a connected and real-time economy

Striking balance between self-autonomous systems and human in loop model to develop a transformed supply chain

- Focusing on having an active and intelligent system in place where peaceful collaboration can exist between man and machine

- The environment demands the changing ecosystem to function towards achieving the results in a comprehensive manner

Transformation in operations and working processes

- Deployments, frameworks, analytics, information ecosystems, realities, and aspects need to be aligned to Industry 4.0

- It requires managing the skills, making the right decision, deliver outcomes and capabilities with respect to the changing economic scenario

- Developing real-time solutions, shifting centralized organizational and planning approaches, on-demand planning, and managing uncertainties go hand in hand

- The overall digital transformation and the technological growth facilitate this change towards a more automated and streamlined SCM

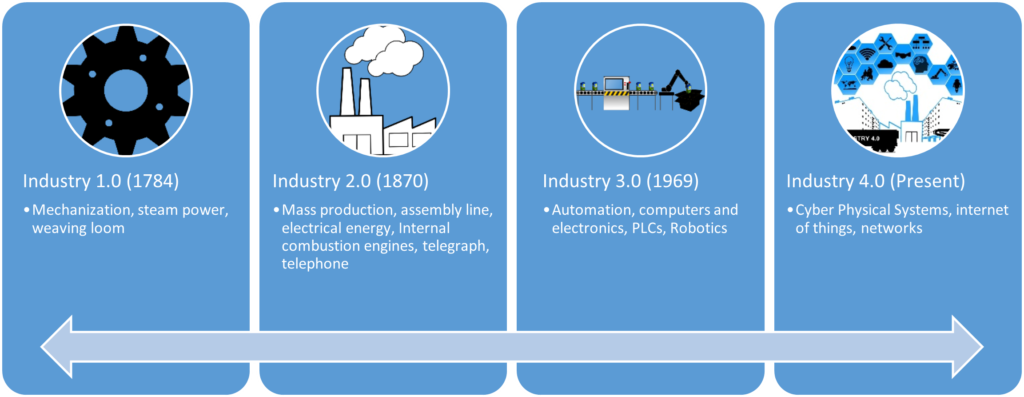

Industrial revolutions

Impact of Supply Chain 4.0 on firms

Eliminating today’s digital waste and adopting new technologies is a major lever to increase the operational effectiveness of supply chains. The potential impact of Supply Chain 4.0 in the next two to three years is huge – up to 30 percent lower operational costs and a reduction of 75 percent in lost sales while decreasing inventories by up to 75 percent.

Technologies & Management strategies

- Traditional supply chains link suppliers to customers in a linear manner, with each firm sourcing inputs from suppliers and in turn delivering its products to customers

- The planning process of each firm is designed to ensure that deliveries are coordinated with the customers’ sourcing activities, which in turn are coordinated with the suppliers’ delivery activities, and that unwanted returns or unneeded products are accounted for

- The term Supply Chain 4.0 can be applied to an integrated supply chain ecosystem, in which information flows in all directions, analytics enable adjustment throughout the supply chain, and response takes place in real time

- To rapidly assess and respond to changes in customer demand, tracking and tracing throughout the supply chain is enabled through sensing technologies such as the Internet of Things (IoT), including radio frequency identification (RFID), Bluetooth, and GSM (global system for mobile communication), which links maritime transport to satellites

- According to a recent PwC study on the rise of Industry 4.0, a third of the more than 2,000 respondents say their companies have started to digitize their supply chains, and fully 72 percent expect to have done so five years from now

Big data, Supply chain analytics & Control towers

- Traditional supply chains link suppliers to customers in a linear manner, with each firm sourcing inputs from suppliers and in turn delivering its products to customers

- The planning process of each firm is designed to ensure that deliveries are coordinated with the customers’ sourcing activities, which in turn are coordinated with the suppliers’ delivery activities, and that unwanted returns or unneeded products are accounted for

- The term Supply Chain 4.0 can be applied to an integrated supply chain ecosystem, in which information flows in all directions, analytics enable adjustment throughout the supply chain, and response takes place in real time

- To rapidly assess and respond to changes in customer demand, tracking and tracing throughout the supply chain is enabled through sensing technologies such as the Internet of Things (IoT), including radio frequency identification (RFID), Bluetooth, and GSM (global system for mobile communication), which links maritime transport to satellites

- According to a recent PwC study on the rise of Industry 4.0, a third of the more than 2,000 respondents say their companies have started to digitize their supply chains, and fully 72 percent expect to have done so five years from now

Big data, Supply chain analytics & Control towers

- Big data analytics are about using data to drive useful business intelligence

- Specific applications of big data analytics include early warning algorithms, predictive algorithms, stock-keeping unit (SKU) rationalization, channel assessment and dashboards

- The desire to collect and distribute data rapidly across a supply chain explains much of the recent enthusiasm for blockchain technologies in the context of supply chain

Blockchain is a distributed ledger technology that allows multiple parties to maintain copies of the same information in different locations, either in an open manner or requiring individual entities’ permission to access the network

- Blockchain protocols encode information, time-stamp them, and enter them as a block into a continuous chain of previous blocks linked to the same transaction

- Blockchain technology also has potential application in port logistics, improving tracking and tracing of containers and coordination in ports such as carriers, ship agents, terminal operators, insurers, customs agents, financial institutions and inland transport

Smart factories/M2M Communications/Driverless Programmable Vehicles

- The application of Supply Chain 4.0 within manufacturing facilities is sometimes referred to as the “smart factory”

- Embedded data collection units, using both automatic identification and data collection and radio-frequency identification (RFID) technologies, can be embedded in most pieces of factory equipment

- The information can be passed from machine to machine (M2M) and handed to a supply chain control tower for decision making

Autonomous robotics simply refers to the control and reprogramming of robotics using bilateral and multilateral machine communication

- Intra-logistics within factories includes the use of driverless vehicles to move materials based on externally-provided information

Predictive maintenance is one of the most important features in a Smart factory and the use of sensors to identify maintenance needs in advance of potential breakdowns reduces costs

- Information from the sensors is made available to service technicians and their supervisors through cloud-based dashboards

- Similarly, the use of predictive analytics and IoT can have a big impact on energy maintenance, both by using energy consumption data to detect potential equipment failures and by continuously modifying equipment settings and process parameters in real time

Smart Logistics and warehouse of the future

- One of the big changes is that the warehouse and the customer become more visible to each other, so that customer purchases trigger not only product movement from the warehouse but also from the manufacturer to the warehouse

- A traditional warehouse involves a good deal of “pick and pack” activity

- If the warehouse serves several firms, the packing may involve selecting packing materials marked with the logo of a particular firm

- Clearly slotting and moving through the warehouse in a time-minimizing manner, can speed up delivery time substantially and reduce errors

- However, within the warehouse, autonomous logistics and robotic transport can be employed to substantially improve pick-and-pack performance

- The use of new technology and human labor are often complements, rather than substitutes, especially in conditions where e-commerce is substantially increasing demand for certain goods

E-commerce is ideal but not uniquely suited for Supply Chain 4.0

- One obvious feature of B2C-commerce is that the process of purchasing involves electronic data entry on the part of the consumer

- This enables information to be captured, preferences to be assessed, and strategies to target the consumer to be implemented, such as the ubiquitous pop-ups which now follow one around the Internet after having viewed a product in a given category

- Although most of the popular discussion of e-commerce is on B2C, nearly 90 percent of e-commerce is in fact business-to-business (B2B)

- B2B commerce can be implemented either through websites, much like B2C e-commerce, or through electronic data interchange (EDI)

EDI is a mature technology through which the computer systems of the buyer and seller are directly connected using a common record format

Impact of Supply chain 4.0 on Customers

- Applications of IoT are increasingly used to facilitate the management strategies of Customer-managed inventory (CMI) or Vendor-managed inventory (VMI) revolutionizing Supply chain management

- In these models, information is initially provided by a customer, for example by scanning a bar code associated with a purchase, and then transmitted up the supply chain to the warehouse/distribution center

- Technologies such as RFID tags then transmit information through an EDI to the distribution center so that orders can be fulfilled

- Future developments in in-store retailing, enabled by IoT technology, will enhance both the customer experience and the ability of stores to pursue advanced management strategies

- Using smart phones, customers may be able to scan barcodes on items to obtain product information or identify other colors or sizes available on the retailer’s website

- VIP customers may be offered virtual coupons on entering the store

- Smart mirrors may allow customers to try on different clothing virtually immersing the customer in a retail environment with the aid of both mobile and in-store devices and may be known as the Internet of Me

- From the management standpoint, smart price tags can be changed in real time based on demand or other needs, and smart shelves in store could detect low inventory, thus providing further support for CMI and VMI strategies

Future of Supply chain 4.0

- Supply chain 4.0 is already here and the traditional framework and work processes that we were accustomed to are slowly disrupted and reinvented to suit the current needs

- Businesses need to move faster and pioneer the paradigm shifts taking place in the enterprise landscape

- Intelligent automation, Internet of Things (IoT), predictive analytics, advanced robotics, big data, and more technological innovations are altering the journey of the supply chain industry every day

- If modernization and technological intervention happens seamlessly across the processes, the supply chain paints a highly autonomous, agile, and predictive picture in its stage of maturity

Conclusion

The transformation into a digital supply chain requires two key enablers – capabilities and environment. Firstly, capabilities regarding digitization need to be built in the organization and require targeted recruiting of specialist profiles. Secondly, a two-speed architecture/ environment needs to be implemented meaning that while the organization and IT landscape are established, an innovation environment with a start-up culture must be created.

This “incubator” needs to provide a high degree of organizational freedom, efficiency, speed and flexibility as well as state-of-the-art IT systems to enable rapid cycles of development, testing, and implementation of solutions.

Read More: Electric Vehicles in Supply Chain